SUPER SALE - Buy Used Machines

GHC Short-fiber Airlaid Line

Width: 660mm | YOC: 2015-2023

This short-fiber aillaid line is ideal for the production of hydrogen bonded airlaid. Application of the end product can include pre-made cores (for absorbent products), such as underpads, food pads, meat pads, fruit pads, etc.

Technical Specification of the Airlaid Line

75 - 400 gsm max mechanical speed 65m/min, average running speed 60 m/min (products 75-160 gsm).

Bottom Tissue Unwinding System

- Two pneumatic tissue loading bars, max roll diameter 35”/890mm (including the core) mm and max roll width 27.5”/700mm

- Automated tissue splice switch over

- Automated tissue tension bar bracket

Defibration System

- Two hammer mills and two pulp unwind stands, width of pulp sheet 23”/600 mm, roll diameter 19”/483 mm

- Two volumetric fibre web feeders

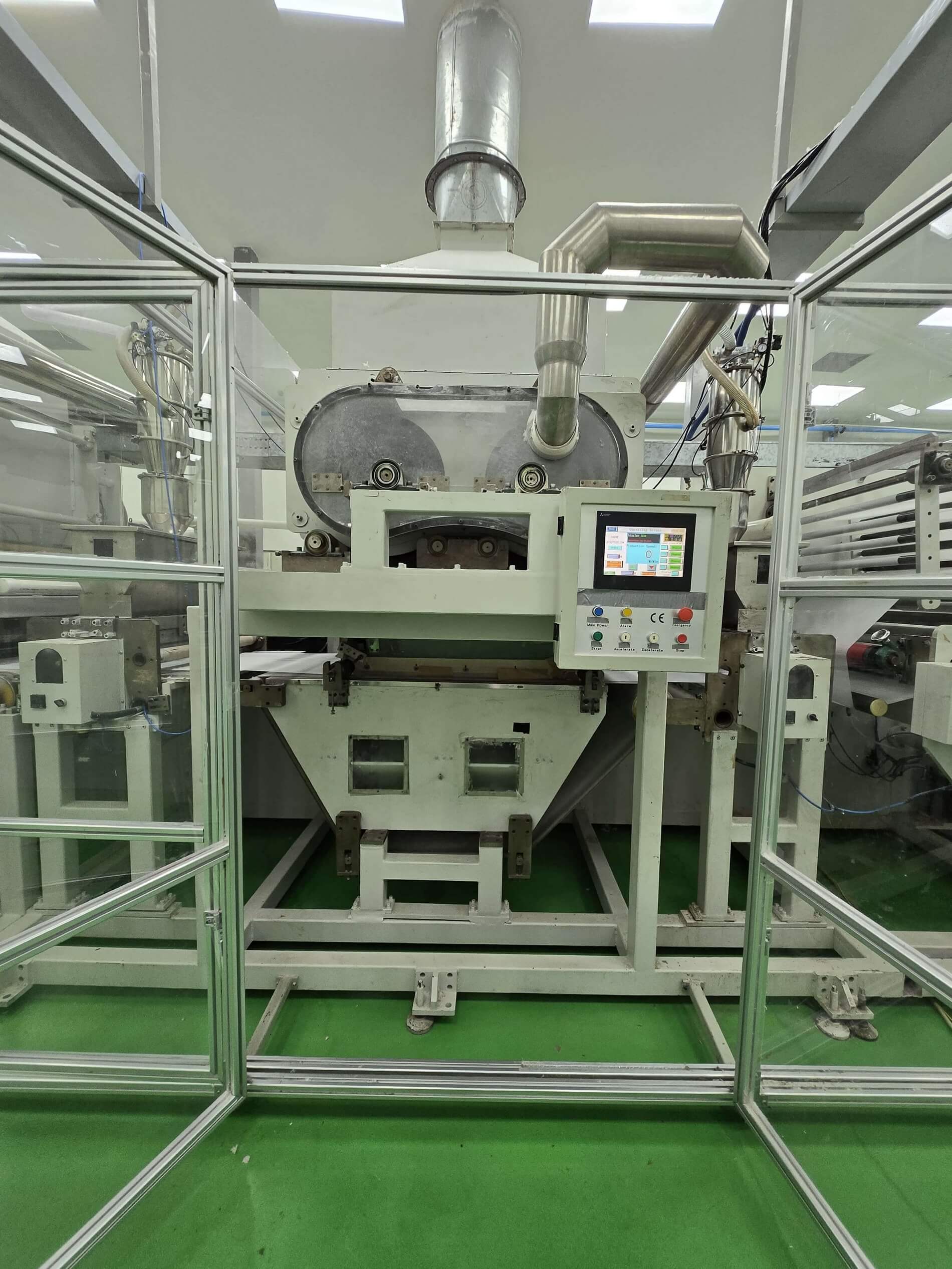

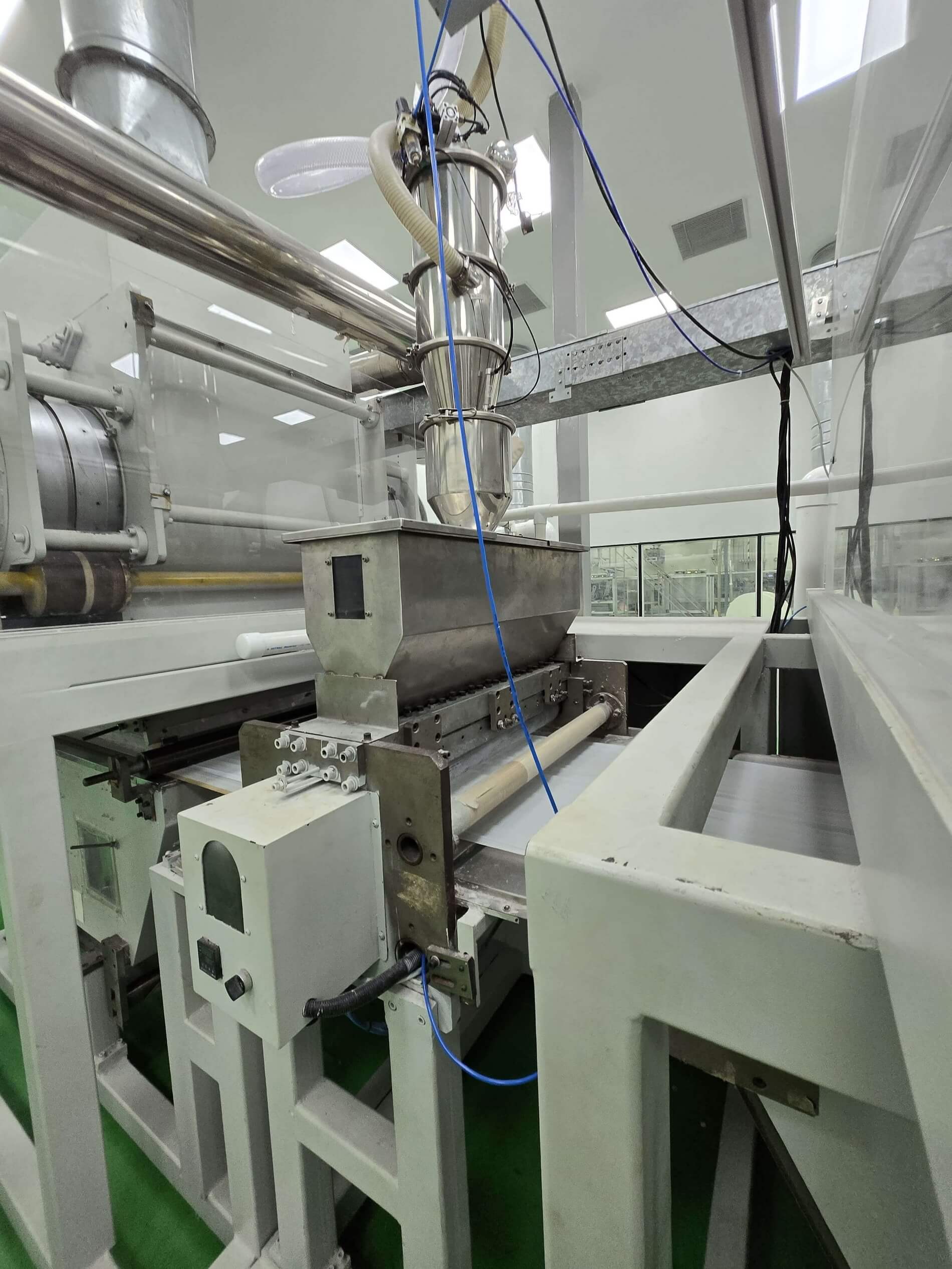

Web Forming System

- Two web forming heads

- Two vacuum chamber systems including fan

- Two atomizing humidification systems

- Two blowers with dust collector

Rewinding and Splicing Systems

- Six adjustable width splicing blades

- Max roll width is 26”/660mm

- Max roll diameter 42” /1070mm

- Automated roll splicing blade

- Automated winding roll changeover

- Trimming waste collection unit

Top Tissue Unwinding Systems

- Two pneumatic tissue loading bars, max roll diameter 35”/890mm (including core) mm and max roll width 27.5”/700mm

- Automated tissue splice switch over

- Automated tissue tension bar bracket

Web Transfer System

- Two conveyor belts travel systems

Embossing System

- Heat press electrical oil driving roller

- Compacting embossing press with electrical oil boiler

Electrical System

- Ten A800 Mitsubishi Electric converters

- Ten Melservo-J4 Mitsubishi Electric servers

- Sixteen Danfoss VLT converters

- Ten Sinovo inverters

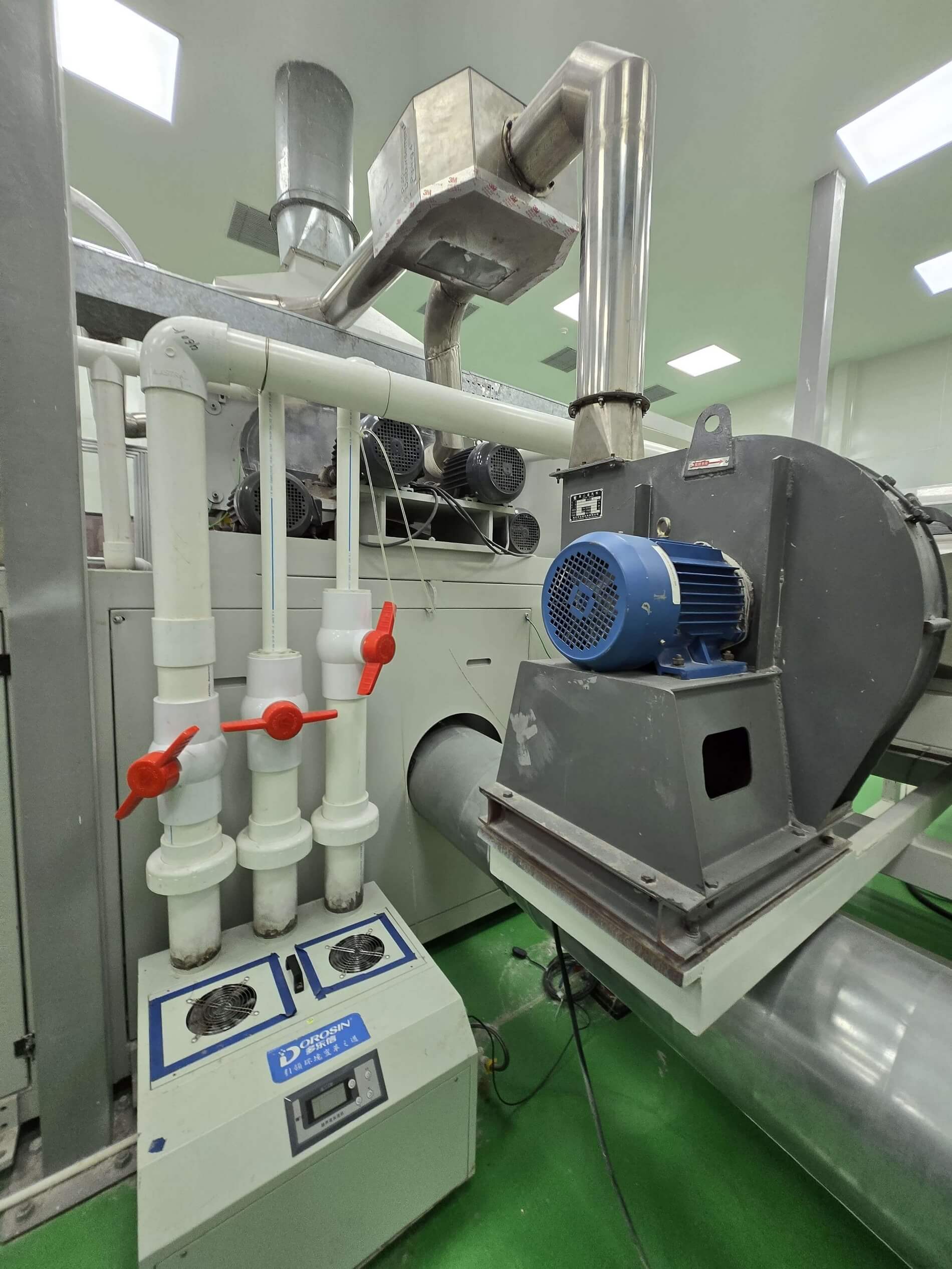

Dust Collection System

- Brand new in 2023

Optional Add on: Gauge sensor

- A new (2024) Jasch Model No.: JIL 400K GSM g

Price

- Available on request

Location

- This airlaid line was originally installed in the US

- Current Location: FCA India

Line Trial Run

- The Airlaid Line is installed and operational, ready for trial anytime, within one week's notice.